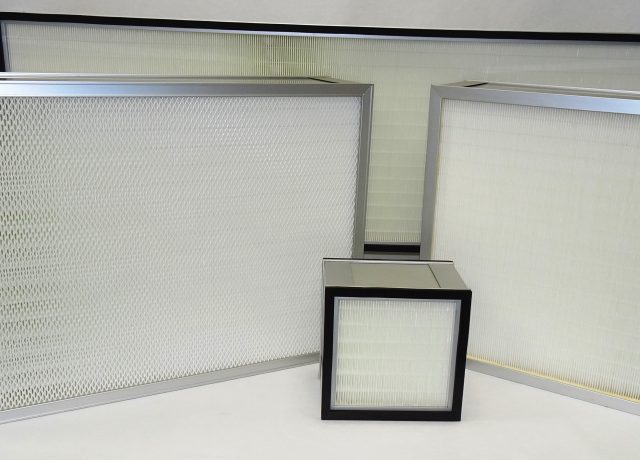

HEPA And ULPA Critical Air Filters

A global market leader and pioneer of advanced medical devices examined our manufacturing and filter testing capabilities, and then chose us to develop an ULPA filter for a surgical suit capable of filtering 99.9995% @ 0.12 micron with a pressure drop of 0.75″ w.g.

They wanted raw material alternatives capable of killing microbes on contact, including Methicillin-resistant Staphylococcus aureus (MRSA), the leading cause of hospital staph infections.

APC determined that an ULPA filter capable of 99.9995% @ 0.12 micron with a pressure drop of 0.75″ w.g. was required to operate at 113° F with a 100% positive seal.

APC engineers made alternative raw material selections and performed 3D fluid dynamic simulations on several imaged designs to meet the client’s filter size, pressure drop and performance criteria. Prototype medical ULPA filters were created, tested and approved in three weeks.

To learn more about medical device filters, custom HEPA filters, or our other products and services, please contact APC Filtration, Inc.

What is an ULPA Filter Used for?

An ULPA fFilter is also known as an Ultra-Low Penetration Air filter. This type of filter is designed for applications that require the highest level of air purity possible, providing a certain amount of air filtration to keep contaminants out. These filters are essential in environments where even a microscopic contaminant can have serious consequences, often in medical and laboratory settings.

In a medical setting, an ULPA filter might protect surgery rooms from airborne pathogens where biohazards are a concern. Another setting where these filters are critical is in semiconductor manufacturing, where contamination from a single particle can destroy sensitive electronics and equipment.

ULPA filters must remove a minimum of 99.999% of particles of microns between the sizes of 0.1 and 0.2. This is an extraordinary level of filtration, making them a critical component in pharmaceutical manufacturing, semiconductor fabrication, and laboratory environments.

Choosing the Best Air Filter for Your Application

In choosing the right air filter for your application, it’s important to consider the operating conditions the filter will be used in, as well as performance specifications to which you need it to adhere. Beyond that, the OEM specifications for the equipment or system the filter will be used in must be considered, as well. The requirements for choosing the best air filter make it a no-brainer for choosing APC Filtration, where every filter is custom designed to take all these factors into consideration.

The Difference Between ULPA and HEPA Filters

Both ULPA and HEPA filters provide a high-efficiency filtration based on particle removal. While HEPA filters are significantly more well known, they differ greatly in their capabilities and applications, and ULPA filters are more often used in specialty applications.

HEPA filters must capture 99.97% of all particles at 0.3 microns, which makes them well suited to general purpose uses where health is a concern, such as hospitals and clean rooms. ULPA filters, on the other hand, must achieve 99.999% efficiency at even smaller particle sizes, between 0.1 and 0.2 microns. Because of the higher efficiency, however, these filters are more difficult to manufacture and are used in more extreme applications.

Are ULPA or HEPA Filters Better?

While it’s easy to presume the ULPA filter might be better automatically based on its ability to filter more particles at a smaller size, it’s not always the right choice for the application. HEPA filters, if they do the job well, are typically more accessible and less expensive, making them sufficient for many applications. HEPA filters also typically have lower maintenance requirements and a reduced energy consumption compared to ULPA filters. ULPA filters, on the other hand, are best in use cases where it’s critical to maintain a contaminate-free environment. These filters are also ideal when working with hazardous biological materials, as well as when operating in ultra-clean environments.

Custom Filter Design

From concept through production, APC has what you’re looking for. We deliver specialized filtration solutions that are engineered to meet your exact specifications for any application. Four decades of experience in serving a diversified range of business sectors and industries allows us to tackle complex filtration challenges all while maintaining the highest quality standards possible for a global reach. Using a systematic approach to identifying your needs in a custom filter, we simulate real use-case environments to ensure your filter is as reliable as possible.