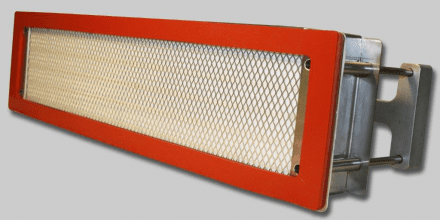

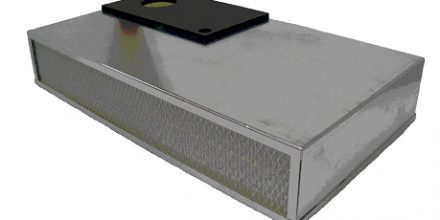

Industrial Vacuum Air Filters

APC provides air filter design, engineering, manufacturing and filter testing to global OEMs of industrial vacuum systems. We design critical air filters that meet or exceed standard filter performance at capturing many types of dust with custom-designed features to make filter installation and removal quick, easy and safe for the operator.

An efficient vacuum system will reduce work downtime, reduce suction loss over a longer time frame and improve workplace safety, ultimately saving your company time and money.

APC ’s engineering team has designed a number of custom and critical air filters to meet the needs of vacuum OEM’s. We manufacture secondary and primary filters, vacuum intake filters and vacuum motor exhaust filters to name a few.

We specialize in providing top-notch industrial vacuums with filters that are equipped with cutting-edge technology. Our reliable filters ensure optimal performance and clean air in various industrial environments. Trust us for your filtration needs!

Vacuum Filters Rated for the Hardest Jobs

In manufacturing, industrial filters face extreme challenges. Our filters are engineered to handle demanding applications, such as filtering out metal shavings, concrete dust, chemical powders, and other types of abrasive or caustic materials. Even when collecting fine particles that quickly clog standard filters, our high-efficiency customized vacuum filters stand the test of time, rated for the hardest jobs.

Our engineers rigorously test, design, and optimize your custom filters to ensure they will resist tearing, maintain their structural integrity under high suction forces, and provide consistent performance, even in harsh conditions.

Each filter goes through prototyping with the assistance of computational fluid dynamics to ensure airflow is maintained while capturing particles ranging from visible abrasive debris to microscopic dusts, ensuring reliable performance in any application. From metalworking to pharmaceuticals, filter failure isn’t an option.

How Do Our Industrial Vacuum Filters Make Cleanup Safer?

Industrial cleanup typically involves hazardous materials and a range of caustic substances that pose a significant risk to both workers and the environment around it. Careful cleanup is required in any part of the process, and custom vacuum filters can incorporate multiple safety features into the process to help enhance safety, protecting workers during cleanup and regular maintenance.

Depending on your facility’s individual needs for a filter, we can even help you design a filter that prevents collected materials from becoming airborne again during disposal, securing potentially harmful particles in the vacuum chamber.

Filters That Meet Your Specifications

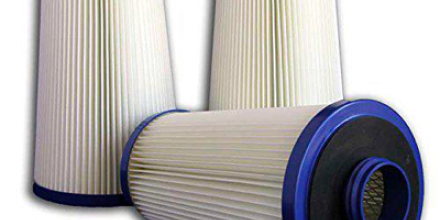

At APC Filtration, we understand that industrial systems come in a wide range of configurations, sizes, and capacities. Each of these vacuums have unique filtration requirements, and your application can have its own set of requirements to enhance safety and security depending on the environment and materials collected. Our custom filter design process begins with a detailed analysis of your specifications, including airflow requirements, particle size distribution and operating environment.

Our engineering team then uses computational fluid dynamics modeling to prototype a custom filter that performs at the level of safety and security you need, all while minimizing maintenance requirements and enhancing lifespan. Our ISO certified process ensures each filter meets your specifications, providing a consistent level of performance across production runs.

Custom Filters for Your Specific Filtration Equipment

Working closely with your team to determine the specifications for your application, industry, and equipment, our engineers excel in developing custom filters that integrate with your existing equipment, all with the enhancements and unique qualities that you require on the job.

Whether you need filters with specialized shapes, specific filtration characteristics, or unique mounting systems, we can deliver the solution that matches your requirements. Every custom order goes through an extensive prototyping and testing phase to validate its performance before full production begins. This ensures that the product meets your technical specifications while also providing practical benefits in real applications.

How Do You Clean an Industrial Vacuum Filter?

With the right engineering team and access to the right materials, any industrial filter can be designed to withstand abrasive debris or dust particulates that typically clog other types of standard filters. That said, custom industrial filters are not often reusable. If reusability and washability are a desired feature in your cleaning process, we can create a custom filter that performs through multiple washes, both dry and wet, to dislodge particles without damaging the filter material.

For these types of filters, we would provide you with detailed cleaning protocols for each type of filter, with unique safety precautions and specialized coatings that extend the intervals between cleanings.

What Type of Vacuum Filter is Best?

The type of vacuum filter that is best for your application depends on your specific requirements. Our team can listen to your use case and suggest a filter that suits your needs. We offer multiple filter types, including filters that serve as a primary collection filter for large particles, or secondary filters for fine dust. We also design specialized filters for your industry that can withstand a range of temperatures, pressures, and materials including fluids.

Every filter we makeis created by considering your needs for particle size and type, environmental conditions, regulatory compliance, and air flow requirements. We work with you to design and prototype the most appropriate filter type based on your needs and performance requirements, so you have a custom-designed filter and accessories for all your workplace needs, getting work done more efficiently and keeping personnel safer.

Contact APC Filtration for Your Needs Today

Ready to work with our engineering team to prototype a new filter for your unique application? Get in touch today and talk to us about your specific use case. We’re ready to help you make your vacuum filtration easy, safe, and efficient in any work environment.

Meeting the needs of your vacuum OEM standards and specifications, we create filters that improve work quality and safety while integrating seamlessly with your existing equipment. With over four decades as a provider of custom goods for a diversified range of business sectors, we are a trusted and reliable name in filtration.