Aircraft Cabin Air Filters

Passenger aircraft cabins can be breeding grounds for many pathogens. Every time someone sneezes, millions of microorganisms are released into the air we breathe. A variety of pollutants, viruses, pollen, bacteria, and microscopic dust can contaminate cabin air and trigger irritants to humans.

AEROSPACE AIR FILTRATION SOLUTIONS

In this enclosed environment it is vital to maintain air purity to minimize harmful particles from circulating throughout the cabin and cockpit. A well-maintained high-performance HEPA filtration system is important for the maintenance of a healthy and comfortable atmosphere for passengers and crew.

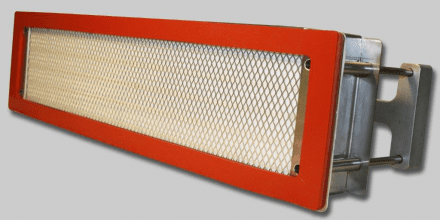

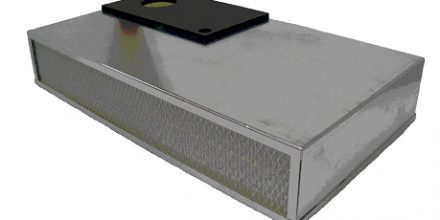

APC Filtration is a trusted partner for aerospace industry filtration needs. Our cutting-edge solutions cater to diverse aerospace applications, including cabin air filters, engine intake filters, and avionics vent filters. We utilize advanced filtration technologies, adhering to stringent industry standards to ensure optimal performance, efficiency, and safety.

Our team of experienced engineers works closely with customers to deliver tailored solutions for unique challenges. With a commitment to excellence and reliability, APC Filtration continues to be at the forefront of aerospace filtration, safeguarding passengers, crew, and equipment during every flight.

Explore our aerospace filtration solutions today!

Custom Filters for Aerospace Applications

Bringing four decades of critical air filter expertise to the aerospace industry, APC Filtration delivers innovative solutions that can meet the standards required for aircraft and aerospace applications. Our ISO certification and comprehensive engineering abilities guarantee that every filter will precisely match specifications, all while maintaining the highest quality standards possible.

We develop custom aerospace filtration solutions with precision thanks to an exceptional engineering team that uses computational fluid dynamics for fast prototype modeling to help us understand your individual use cases. This allows us to meet and exceed your project requirements while maintaining a global presence for all aerospace industries.

At APC Filtration, our approach to custom design begins with a thorough analysis of your use case. We work closely with you to determine what your filter goals are, how and where the filter will be used, pressure drop requirements, efficiency needed, and more. We utilize advanced synthetic fibers, multi-layer composites, and specialized treatments to achieve the best performance in any aerospace environment. We consider aircraft-specific parameters, including your installation constraints and operating temperature ranges. We can also consider maintenance access requirements and environmental control system specifications in any filter, developing solutions that integrate seamlessly with your aircraft’s existing systems.

Aerospace Filters for the Defense Industry

In the defense industry, aerospace filters play a critical role in protecting both people and equipment. Whether used in internal operations or military applications, aerospace filters are essential in allowing an aircraft to operate in a wide range of environments and altitudes, all while keeping the interior cabin safe and free from harmful airborne particles, fuel or debris.

From desert conditions to smoke, these crafts usually require specialized filtration systems that work reliably and keep personnel safe from threats that occur during war. From chemical to biological materials, APC Filtration can design and create customized air filters that are specially integrated into any military aircraft to ensure the safety of its crew during missions.

Ground support is another area where aerospace filters can come into critical use. While aerospace filters specifically must be able to withstand high altitudes and potential impacts, we understand that ground support equipment requires the same kind of safety precautions and resistances. Regardless of how or where they’re used, the filters we design are put through rigorous quality testing and design specifications to meet your customized needs.

What Are the Air Filters in Aviation?

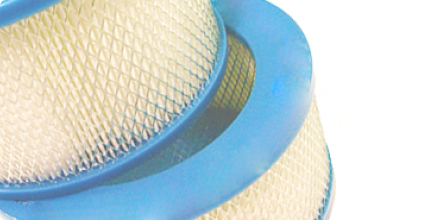

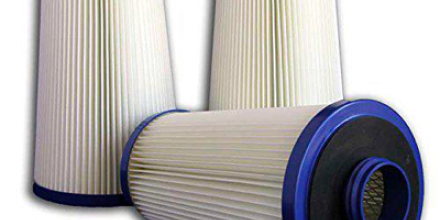

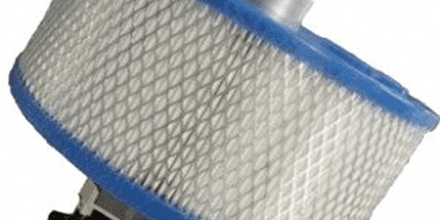

Aviation air filters are critical parts of aerospace and flight equipment that keep occupants safe from external debris, pollutants, and airborne chemicals that might otherwise cause respiratory harm. While the aviation industry typically has a wide range of filters in specific use cases, most aircraft have multiple filters in use, each designed for particular purposes, and each located in different areas of the aircraft or equipment for additional redundancies. HEPA filters, along with activated carbon filters, provide exceptional levels of protection, and are the primary defense against airborne contaminants like gas and bacteria. These filters capture bacteria, pollen, and other particulates as small as 0.3 microns. These filters do an exceptional job performing under varying pressure conditions, consistency, and filtering out foreign particles. In addition to these filters that typically protect the occupants of an aircraft, many aircraft engines require air intake filters to prevent damage to the aircraft itself. These protective filters prevent harm from foreign objects, protect against ice rain and snow, and help the engine maintain optimal airflow and performance for additional reliability in the air. These filters must perform rigorously under extreme temperatures and varying pressures while maintaining structural integrity.

Custom Filter Design

From concept through production, we’ve got what you’re looking for. APC Filtration is an ISO 9001:2015 certified manufacturer with over 40 years of experience in producing custom air filters for critical use cases across a wide range of industries and services. From design, engineering, and testing, we set the standard for OEM specifications in industrial, commercial, and household equipment throughout North America and Europe. Whatever you need designed, fitted, and shaped to your unique specifications – we can handle it. Our specialized rapid prototype modeling uses computational fluid dynamics to design, model, and test all air concepts for fit, function, performance and longevity with your specific equipment and application – all before they’re ever designed.

Our material scientists work closely with top industry suppliers to incorporate the latest technologies into our aerospace filtration media to ensure everything we produce can withstand the rigorous demands of the job. We can select materials based on specific application requirements, considering factors such as operating temperature and pressure differentials, as well as exposure to a range of contaminants to ensure each filter can withstand practical, everyday use.

Extending beyond standard ISO standards, our quality control measures are dedicated to each individual design. We understand that custom filtration in such a demanding industry requires precision designs and prototyping. We ensure complete traceability and compliance with aerospace industry standards, all to exceed your project specifications. We keep complete records of test results, performance data, and the manufacturing process and prototyping specifications to keep every part of the process simple for you and your project. This forward-thinking approach from our engineering department ensures you receive the most advanced filtration solutions available today.