HEPA and ULPA Filters for Hospital Equipment

Healthcare facilities are always impacted by risks and hazards. Today, all viruses, including SARS-CoV-2, the virus that causes COVID-19, Delta, Omicron and other variants have amplified risks with new unknowns and protocols that change daily. Just as healthcare workers are committed to protecting others, APC Filtration is committed to helping them by filtering the air they breathe.

Critical Air Quality requires 100% Compliance

Hospitals are focused on HEPA and ULPA air filtration in their ventilation, waste management systems, smoke evacuation equipment, air pumps, and patient air warming systems to minimize the spread of viral and bacterial biohazards or contaminants.

In environments and procedures with high risk exposure to viruses, HEPA filters and ULPA filters remove these invisible airborne contaminants to provide environmental protection for healthcare professionals and patients.

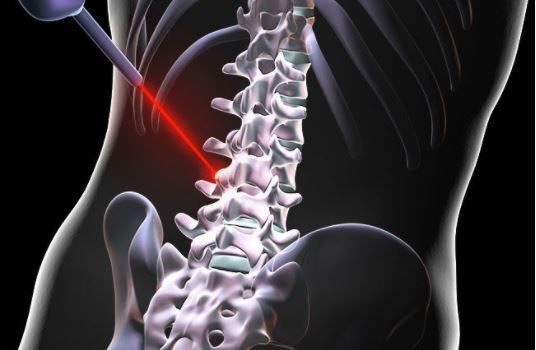

It is proven that smoke from laparoscopic surgery is aerosolized by the thermal destruction of tissue throughuse of lasers or electrosurgical devices during surgery. This smoke can contain harmful bacteria, viruses and biochemical toxins. HEPA and ULPA filters provide viral and bacterial filtration to protect staff and patients from the harmful effects that surgical smoke may have.

HEPA filters provide a minimum of 99.97% efficiency down to a 0.3 micron particle size.

ULPA filters provide a minimum of 99.999% efficiency down to a 0.1 micron particle size.

APC Filtration rigorously tests each and every HEPA and ULPA filter in our ISO 6 test lab to ensure compliance meets or exceeds IEST and/or EN test standards. We are committed to help stop the spread of COVID-19 by using our resources to manufacture HEPA and ULPA filters for global medical device OEMs (original equipment manufactures).

Contact us today to learn how we can meet your air filtration needs and help stop the spread of SARS-CoV-2.

HEPA filters provide a minimum of 99.97% efficiency down to a 0.3 micron particle size.

ULPA filters provide a minimum of 99.999% efficiency down to a 0.1 micron particle size.

APC Filtration rigorously tests each and every HEPA and ULPA filter in our ISO 6 test lab to insure compliance meets or exceeds IEST and/or EN test standards. We are committed to help stop the spread of COVID-19 by using our resources to manufacture HEPA and ULPA filters for global original equipment manufactures (OEM’s) of medical devices.

What is a Medical Grade HEPA Filter?

Medical grade HEPA filters are specifically designed and engineered for use in critical healthcare environments that standard HEPA filters cannot perform reliably in. These are the highest tier of air filtration technology that medical professionals require to do their job safely while keeping patients safe and equipment sterile. Manufactured under stringent quality control protocols, the key differences in medical-grade HEPA filters compared to standard HEPA filters is in their individual quality assurance testing. Each filter undergoes a test to verify the performance of 99.97% efficiency rating with particles the size of 0.3 microns. Medical grade specific filters must maintain their efficiency ratings under varying conditions, such as different pressure conditions or rooms with varying flow rates, removing bacterial and viral contaminants from the air without losing performance quality or reliability in use. At APC Filtration, we are proud to provide custom hospital HEPA filters that meet and exceed medical grade testing procedures and can be built to your unique specifications. We ensure our filters are designed and prototyped under actual use conditions, providing you with the most reliable filters possible.

Different HEPA Standards

HEPA standards are governed by strict industry classifications, with two primary organizations defining the standards based on application and effectiveness. We ensure that each of our customized filtration products meet and exceed these standards, with each of our products ISO certified and exceeding your project requirements.

Each HEPA class is graded by its retention total – or the number of particles that are trapped by the filter successfully. E10, in this example, can retain 85% of particles. An E12 can retain up to 95% of all particles. Then we move onto the H series, where H13 and H14 can retain 99.95% and 99.995% of all particles respectively. These are considered the minimum standard of HEPA filters and typically serve their purpose in the setting of a hospital air conditioning system, surgery room, or isolation unit. The U series of HEPA filters come in the sizes U15, U16, and U17. These filters can all retain particles at 99.99% efficiency or greater, each to varying degrees for different use cases. These filters serve to protect both health care workers and patients from airborne contaminants in a wide range of facility use cases.

What are HEPA Filters Made of?

HEPA filters, particularly ones that hospitals use either in a static or portable system, are constructed with the most advanced materials on the market with precise manufacturing that allows them to achieve such high efficiency ratings, combatting up to 99.97% of bacteria sizes 0.3 microns or larger. At the core most HEPA filters are borosilicate microfibers, ranging from 0.5 microns and larger, arranged in varying densities and patterns to capture as many particulates as possible. This specialized design of glass fibers creates a deep matrix to capture particles without sacrificing airflow throughout the filter media.

These filter fibers are also pleated to reduce air resistance in the filtration system. An antimicrobial coating on the filter prevents water or other moisture from entering the filter and creating potential for mold growth and mildew. Everything is then sealed within a coating like silicone or polyurethane that are compliant with medical grade industry regulations.

Supporting components can be added to HEPA filters depending on the specific system and use cases. An upstream pre-filter can capture larger particles and reduce the wear on smaller filter media, while additional security can be added downstream to add additional protection against contaminants. In addition to these additional security measures, UV lighting can be added to the system to purify any final contaminants that make it to the downstream filter media. Airtight installation is essential anywhere a hospital-grade HEPA filter is installed, as these custom filters are selected specifically for their ability to filter out biohazardous contaminants.

How Does a HEPA Filter Work in a Medical Environment?

HEPA filtration is an essential part of the medical industry, keeping hospitals and care facilities safe from contaminants, protecting both medical staff and patients. Typically operating within laminar flow configurations, HEPA filters maintain consistent airflow patterns that prevent potential contamination. For example, a positive pressure environment in an operating room, and a negative pressure environment in another room is achieved through the precise control of filtered air. These systems are continuously monitored for their pressure differentials, and filters can assist in maintaining optimal pressures throughout different rooms on the same air system. Filtering processes environmental contaminants, aerosolized medications, surgical smoke and infectious biohazard droplets all in the same system that optimizes airflow.

Contact us today to learn how APC Filtration Inc., can meet your air filtration needs and help stop the spread of SARS-CoV-2.