Aseptic Processing Equipment – Custom HEPA Filter Design

Industry: Food & Pharmaceutical Equipment

Application: Aseptic Processing

Aseptic processing is the process by which a sterile (aseptic) product (typically food or pharmaceutical) is packaged in a sterile container in a way that maintains sterility.

Sterility is achieved with a flash-heating process (temperature between 195 and 295 °F (91 to 146 °C) which retains more nutrients and uses less energy than conventional sterilization techniques. Pharmaceutical Sterile processing includes use of clean rooms, bacteria retaining filters, dry or steam heat. Aseptic food preservation methods allow processed food to keep for long periods of time without preservatives, as long as they are not opened.

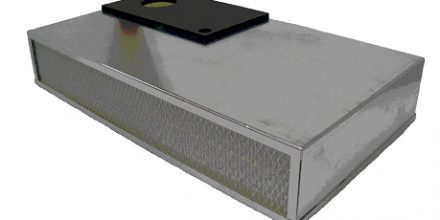

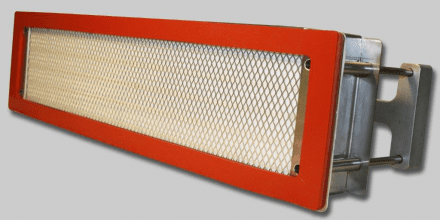

APC was contacted by the equipment manufacturer to design a custom made HEPA filter for their aseptic processing equipment. The filter body and installation assembly was designed entirely out of 316, #4 brushed stainless steel to withstand the disinfectant cleaning cycles that use vaporized hydrogen peroxide.

Custom designed packaging was designed to prevent filter damage and insure filter integrity when our client required drop shipping replacement filters to their global equipment clients.

To learn more about this or our other biological safety cabinet filter projects, or about our other products and services, please contact APC Filtration, Inc.