APC Develops Custom Inlet Filter for Dual Filtration Paint Sprayer

Industry: Appliance – Industrial / Commercial

Application: Turbine Paint Sprayer

A major OEM of paint spray equipment contacted APC to advance their flagship 9.5 PSI Dual Filtration Paint Spray System to its maximum capacity. Their current system uses two foam media filters to filter intake cooling air and paint atomizing air. They wanted to improve air atomization to achieve the finest and cleanest spray for as many coatings as possible.

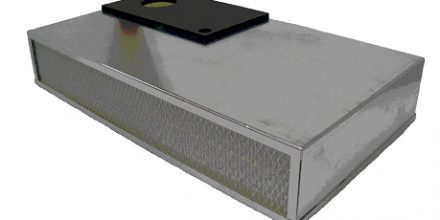

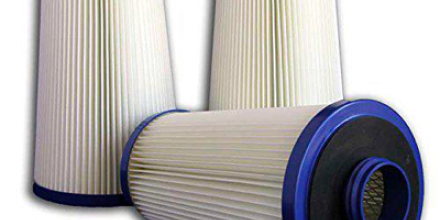

APC engineer’s spent over two years creating a total of 7 filter prototypes. The 7th air filter design was a high efficiency pleated media filter, encapsulated in a plastic frame assembly achieving:

1. A minimum filtration efficiency of 99.30% at 0.3 micron with a 50% reduced pressure drop to 0.6″ H2O at 32.4 CFM.

2. 100% filtration efficiency at 1.0 micron at 65 CFM maximum airflow with a maintained pressure drop of 1.21″ H2O.

3. A new and revolutionary six-stage turbine spraying system was developed, producing 11.5 PSI from 9.5 PSI, becoming the industry’s first turbine sprayer to achieve full HVLP capability.

To learn more about this six-stage turbine paint sprayer project, or about our other products and services, please contact APC Filtration, Inc.

Our RFQ process provides a defined and accurate assessment of your filter requirement and performance deliverables to ensure our filters meet and/or exceed your expectations. We design custom, unique, proprietary and/or patented air filters for our clients to meet both North American and European test standards.