Aseptic Packaging of Pharmaceutical Products

Achieving strict sterility standards is crucial in the pharmaceutical industry, especially when it comes to packaging equipment.

The sterilization process of pharmaceutical packaging equipment involves the use of clean rooms, bacteria-retaining filters, and either steam or dry heat. This is to ensure the health and safety of workers, patients, and medical professionals. From manufacturing to filter replacement, it is important to maintain adequate sterility throughout all processes for all pharmaceutical items.

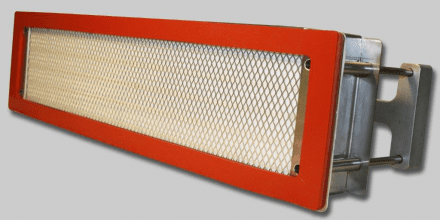

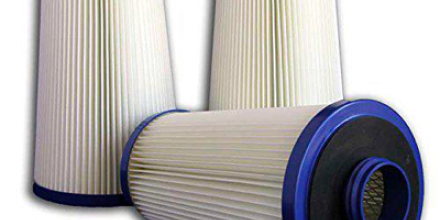

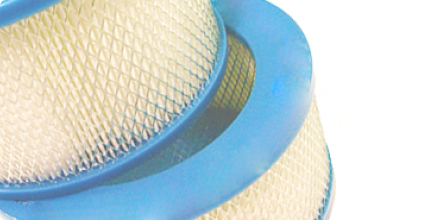

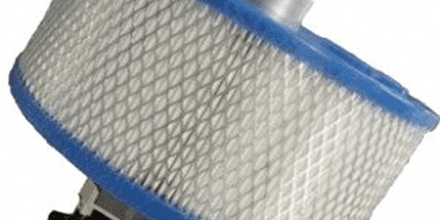

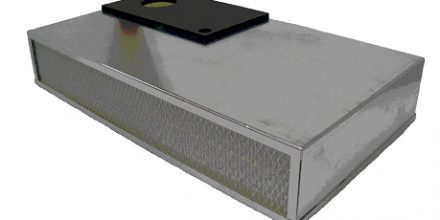

APC Filtration Inc. understands the importance of critical air filter design and engineering for pharmaceutical and aseptic packaging OEMs. APC is an ISO 9001:2008 certified manufacturer with over 40 years of experience providing customized filter solutions to meet the unique needs of our clients.

Our pharmaceutical-grade filters are designed to meet filter efficiencies ranging from HEPA 99.97% @ 0.3 micron to ULPA 99.999% @ 0.12 micron. We provide our OEM clients with unique, proprietary and/or patented air filter designs. We also provide rapid prototype modeling and filter testing to ensure compliance to North American and European test standards.

For more information about how APC can assist with the development of critical air filters for pharmaceutical and aseptic packaging equipment, please contact us.

Custom Filter Design

From concept through production, we’ve got what you’re looking for.